- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-18 Origin: Site

If you have ever unboxed a new smartphone, you have seen a rigid box in action. This packaging uses thick, sturdy materials that do not collapse, keeping your product safe from damage. Rigid box packaging stands out for its solid shape and premium feel. You often find rigid boxes protecting high-end electronics and luxury items.

Rigid boxes for gadgets such as smartphones and watches

Rigid plastic trays for headphones and cameras

Minimalist rigid boxes for high-end electronics

Each rigid box supports your product, prevents crushing, and adds a touch of style to gift packaging.

Rigid boxes use thick, sturdy materials that protect products and create a premium, luxury feel.

These boxes come pre-assembled with specialty paper wraps, offering strong protection and elegant designs.

Rigid packaging is ideal for fragile or high-value items like electronics, jewelry, and cosmetics.

Custom rigid boxes allow branding with logos, colors, and special finishes to enhance customer experience.

Rigid boxes are reusable, durable, and often made with eco-friendly materials, supporting sustainability.

You see rigid box packaging everywhere, especially when you buy premium products. Rigid boxes use thick chipboard, usually between 2.5 mm and 3.5 mm, which gives them a sturdy, non-collapsible structure. This rigid stock protects your product from crushing and damage. You notice the difference as soon as you touch a rigid box. The surface feels solid, and the box holds its shape even under pressure. Rigid box packaging stands out because it delivers a luxury presentation and a memorable unboxing experience.

Tip: Rigid boxes are also called set-up boxes. You often find them wrapped with specialty papers that add texture and color.

Rigid box packaging uses a wrapping process similar to gift wrapping. Manufacturers cut and fold decorative paper, then wrap it around the rigid stock. This process creates a smooth, elegant finish. You can choose from many specialty papers, such as soft touch paper, metallic finishes, black specialty paper, or embossed textures. These options give your rigid box design a premium look and feel.

Rigid boxes come in many shapes and sizes. You find them used for smartphones, luxury gift boxes, and even shoe boxes. Each type of rigid box uses thick rigid stock to create a strong structure. The chipboard thickness varies depending on the product. For example, magnetic rigid boxes use chipboard between 1.5 mm and 3 mm, while boxes for heavy items may use up to 4 mm.

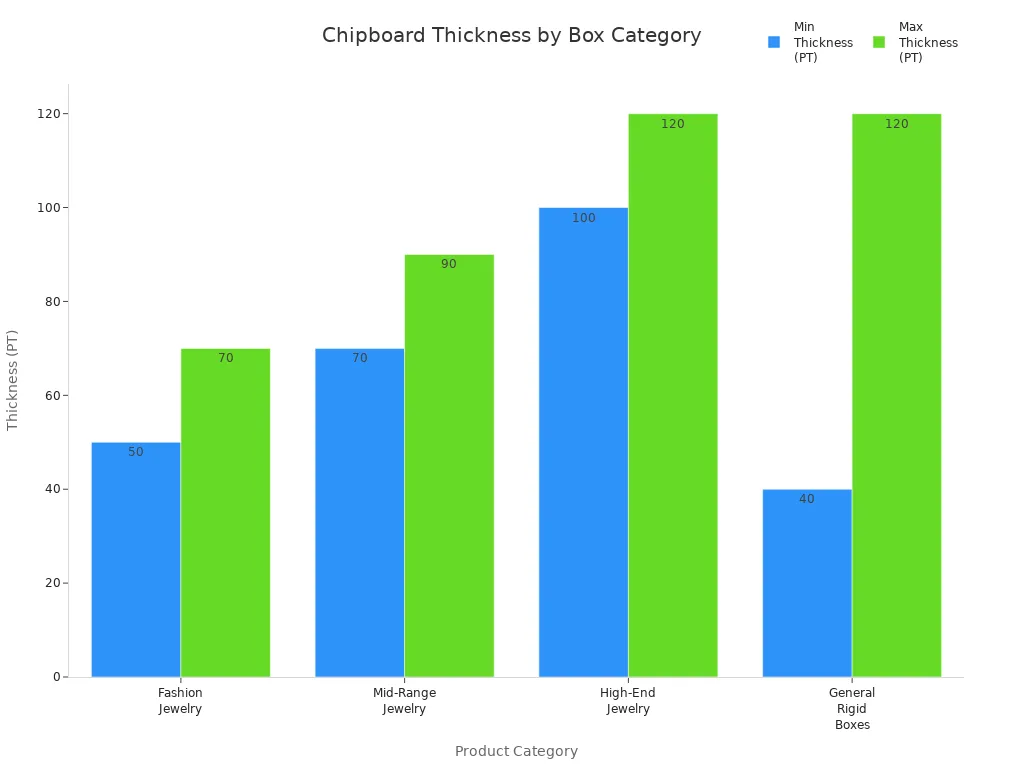

Here is a table that shows the typical chipboard thickness for different types of rigid boxes:

Box Type | Typical Chipboard Thickness | Notes |

|---|---|---|

Full finish rigid box | 2 mm to 3 mm | No chipboard exposed, premium finish |

Magnetic rigid box | 1.5 mm to 3 mm (up to 4 mm) | Used for heavier or fragile products |

Standard greyboard | 1 mm to 4 mm | Thickness depends on product and use |

You notice that rigid carton box packaging uses much thicker material than folding cartons. Here is a comparison:

Feature | Rigid Boxes | Folding Cartons |

|---|---|---|

Material Thickness | 2.5 mm to 3.5 mm chipboard (non-bending) | Thinner paperboard like SBS, SUS, or CCNB |

Construction | Pre-assembled, sturdy, separate lid/base | Cut, scored, folded from a single flat piece |

Durability | High structural integrity, impact-resistant | Moderate, prone to creasing and crushing |

Perceived Value | Premium, luxury, high-end feel | Standard to mid-tier, cost-effective |

Design Complexity | Intricate designs, custom inserts | Versatile printing, simpler structures |

Shipping & Storage | Bulky, shipped assembled | Space-efficient, shipped flat |

Unboxing Experience | Enhanced, memorable, magnetic closures/ribbons | Standard, functional |

Sustainability | Durable, reusable, longer lifecycle | Easier to recycle, lighter materials |

Rigid carton box packaging stands out for its durability and luxury appearance. You get a box that feels premium and protects your product. The manufacturing process for rigid boxes is more detailed than for folding cartons. Rigid box packaging uses thick rigid stock, which is wrapped with specialty paper. This process takes longer and requires more manual labor. You receive a box that is already assembled and ready for your product.

When you choose custom rigid boxes, you can select the type of rigid stock, specialty paper, and box design. You create packaging that matches your brand and product needs. Types of rigid boxes include magnetic closure boxes, lift-off lid boxes, and hinged lid boxes. Each type uses rigid carton box construction for strength and style.

Note: Luxury rigid box packaging often uses soft touch paper or metallic finishes to create a high-end look. These materials make your product stand out on the shelf.

Rigid carton box packaging gives you a premium feel, strong protection, and endless design options. You see rigid boxes used for electronics, jewelry, cosmetics, and other luxury products. The thick rigid stock and specialty paper wrapping create a box that looks and feels special. You make a statement with every product you package in a rigid box.

When you choose a rigid carton box, you select packaging material that stands out for strength and quality. Most rigid carton boxes use high-thickness chipboard, also called greyboard or kraft board. This rigid stock usually measures between 2 mm and 3 mm thick, making it four times thicker than standard cartons. You notice the difference when you hold a rigid carton box. The walls feel solid and do not bend easily. This thickness gives your packaging a premium look and protects your products during shipping.

You often see rigid carton box packaging material wrapped with decorative specialty paper. This layer adds color, texture, and extra durability. Full finish rigid carton boxes use thicker paper and lamination, which improves edge resilience and creates a luxury appearance. Partial finish boxes expose some chipboard, which speeds up production but offers less protection. Inserts made from paperboard, corrugated board, molded pulp, foam, or plastic add shock resistance inside the rigid carton box.

Here is a table showing the main packaging materials used in rigid carton box construction:

Material Type | Description | Durability Rating / Characteristics |

|---|---|---|

Chipboard (Greyboard or Kraft) | High-thickness (2-3 mm) rigid stock forms the structure of the box. Used in both partial and full finishes. | High durability; more robust than folding cartons and flexible packaging. |

Decorative Specialty Paper | Wraps the rigid stock, either partially or fully. Laminated for extra strength. | Enhances durability, especially with lamination; improves edge resilience. |

Inserts (Paperboard, Corrugated, Molded Pulp, Foam, Plastic) | Placed inside the rigid carton box for shock resistance. | Adds protection and stability, boosting overall durability. |

You can see how the choice of rigid packaging materials affects the strength and appearance of your rigid carton box. The right combination of rigid stock and specialty paper creates a rigid box design that matches your brand and product needs.

The structure of a rigid carton box sets it apart from folding cartons. You get a non-collapsible box that keeps its shape and protects your products. Rigid stock forms the sturdy walls, while smooth linerboard layers add flat, protective surfaces. These layers prevent tearing and puncturing, so your packaging stays intact even when stacked or shipped.

Rigid carton box construction uses multi-wall boards and strong adhesives. You benefit from vertical compression strength and cushioning, especially when the box includes fluted mediums between linerboards. This design lets your rigid carton box support heavier loads and resist bending. Advances in coatings and manufacturing precision improve crush resistance and durability.

You notice that rigid carton boxes are heavier and bulkier than folding cartons. This extra weight means your packaging can handle fragile or luxury items, such as electronics, jewelry, or wine bottles. The rigid stock and specialty paper wrapping create a box that feels premium and lasts longer. You get superior protection, high product safety, and a memorable unboxing experience.

Tip: Rigid carton boxes are reusable and provide better protection than folding cartons or corrugated boxes. You can use them for luxury rigid boxes, custom rigid boxes, and rigid gift boxes to enhance your brand image.

You often see rigid box packaging used for luxury products. Jewelry, watches, perfumes, and high-end electronics rely on rigid stock to create a premium look and feel. According to a 2024 market report, rigid boxes account for 38.4% of jewelry packaging. This popularity comes from their durability and elegant appearance. When you open a rigid gift box, you experience a sense of quality and exclusivity. Brands use custom rigid boxes to showcase rings, necklaces, and watches, making each product stand out in retail displays. The benefits of using rigid stock include a strong structure and a memorable unboxing experience. You notice that luxury rigid boxes help brands command higher prices and build customer trust.

Jewelry (rings, necklaces, watches)

Perfumes and cosmetics

High-end electronics (smartphones, headphones)

Designer accessories

Tip: Rigid box packaging often features embossing, foil stamping, and custom inserts to enhance the product’s value.

Rigid box packaging provides a high level of protection for fragile items. You want your product to arrive safely, especially if it is delicate or expensive. Rigid stock forms a tough barrier that resists crushing, moisture, and shocks. Many industries, such as electronics and healthcare, choose rigid packaging for its ability to maintain product integrity. For example, the Benson Box® uses corrugated plastic and custom foam padding to absorb impact energy, protecting fragile contents better than standard cardboard. You see custom rigid boxes with foam inserts or molded liners that keep products secure during shipping. This high level of protection makes rigid boxes ideal for shipping perfumes, electronics, and luxury goods.

Rigid stock resists bending and crushing

Foam inserts cushion fragile products

Multi-layer construction absorbs shocks

You use rigid box packaging to build a strong brand identity. The sturdy construction and premium finishes, such as embossing and metallic foiling, communicate luxury and exclusivity. Custom rigid boxes allow you to add your logo, brand colors, and unique design elements. This attention to detail creates a memorable unboxing experience that customers often share on social media. Rigid gift boxes help your brand stand out in competitive markets. Sustainable materials in rigid packaging also show your commitment to environmental responsibility, which appeals to eco-conscious consumers. The durability and reusability of rigid boxes extend your brand’s presence beyond the initial purchase.

Branding Benefit | Description |

|---|---|

Luxury Appearance | Premium finishes and sturdy design elevate brand image |

Customization | Embossed logos, colors, and inserts reflect identity |

Unboxing Experience | Memorable moments encourage social sharing |

Sustainability | Eco-friendly materials support brand reputation |

Long-Term Visibility | Reusable boxes keep your brand in customers’ homes |

Note: Rigid box packaging helps you create a lasting impression and build customer loyalty.

You have seen how a Rigid Box, like a smartphone box, sets the standard for premium packaging. Rigid box packaging protects your products, boosts your brand, and creates a memorable experience.

Custom rigid boxes offer strong protection and luxury appeal for fragile or high-value items.

Rigid gift boxes and luxury rigid boxes use eco-friendly materials, helping your brand stand out.

Custom rigid box packaging lets you design unique styles that attract attention and build loyalty.

Choose Rigid Box solutions when you want your products to arrive safely and impress your customers.

A Rigid Box uses thick chipboard and specialty paper. You get a sturdy, non-collapsible structure. Regular packaging, like folding cartons, uses thinner materials. Rigid box packaging gives your products better protection and a luxury feel.

Yes! You can design custom rigid boxes with your logo, colors, and special finishes. Custom rigid box packaging lets you choose inserts, textures, and shapes. This helps your brand stand out and creates a memorable unboxing experience.

Luxury brands choose rigid gift boxes because they look elegant and feel strong. You get a premium presentation that matches high-value products. Luxury rigid boxes also protect fragile items and support your brand’s image.

You can reuse rigid boxes many times because of their strength. Many custom rigid boxes use recycled materials and eco-friendly specialty papers. Rigid box packaging supports sustainability and reduces waste.

You often see rigid box packaging for electronics, jewelry, perfumes, and watches. Custom rigid boxes and luxury rigid boxes protect fragile or expensive items. Rigid gift boxes also work well for special occasions and premium gifts.